Discover cost-effective, customizable solutions with free miter saw table plans in PDF format. Build a sturdy workspace, save money, and enhance your woodworking projects with easy-to-follow guides.

Overview of Miter Saw Tables and Their Importance

A miter saw table provides a stable and ergonomic workspace for precise cutting. It enhances accuracy by keeping the saw and workpiece aligned, reducing errors. These tables are essential for woodworking, offering a flat surface for supporting long materials. A well-designed miter saw table improves workflow, allowing for efficient handling of large or heavy stock. It also serves as a central hub for organizing tools and accessories, making projects more manageable. With free PDF plans, you can customize the design to fit your workshop needs, ensuring durability and functionality. This setup is a must-have for both professionals and DIY enthusiasts, streamlining tasks and improving overall productivity.

Why Choose Free PDF Plans for Your Miter Saw Table

Free PDF plans for a miter saw table offer a cost-effective solution for woodworkers and DIY enthusiasts. They provide detailed, customizable designs that cater to various skill levels and workshop needs. With step-by-step instructions, 3D diagrams, and material lists, these plans simplify the building process. You can avoid the high cost of store-bought stands while creating a tailored workspace. PDF formats are easy to download, print, and reference, ensuring clarity and convenience. By using free plans, you save money and gain the flexibility to adapt the design to your specific requirements, making it a practical choice for enhancing your woodworking projects.

Benefits of Building Your Own Miter Saw Table

Building your own miter saw table offers numerous advantages, including cost savings, customization, and improved functionality. By using free PDF plans, you can design a table that fits your specific workshop needs and enhances your woodworking efficiency. A custom-built table provides a stable and level surface, ensuring accurate cuts and reducing the risk of errors. Additionally, you can incorporate features like foldable wings, storage solutions, and mobility options to maximize space and workflow. This project also allows you to practice and improve your woodworking skills while creating a durable, long-lasting tool that complements your miter saw, making it a valuable addition to your workshop.

Safety Considerations and Preparations

Ensure a safe workspace by wearing protective gear and following power tool guidelines. Regularly inspect equipment and maintain a clean, clutter-free area to prevent accidents during assembly and use.

Essential Safety Tips for Working with Power Tools

Always wear protective gear, including safety glasses, gloves, and a dust mask, when operating power tools. Ensure the workspace is well-lit and free from obstructions. Keep loose clothing and long hair tied back to avoid entanglement. Familiarize yourself with the tool’s specifications and operating instructions before use. Maintain a firm grip on tools and avoid overreaching. Never leave power tools unattended or within reach of children. Regularly inspect tools for damage or wear and tear, and ensure all guards are in place. Unplug tools when not in use or during blade changes to prevent accidental start-ups. Proper ventilation is crucial to avoid inhaling dust and fumes. Stay focused and avoid distractions while working with power tools to ensure accuracy and safety. By following these guidelines, you can minimize risks and create a safer working environment for your miter saw table project.

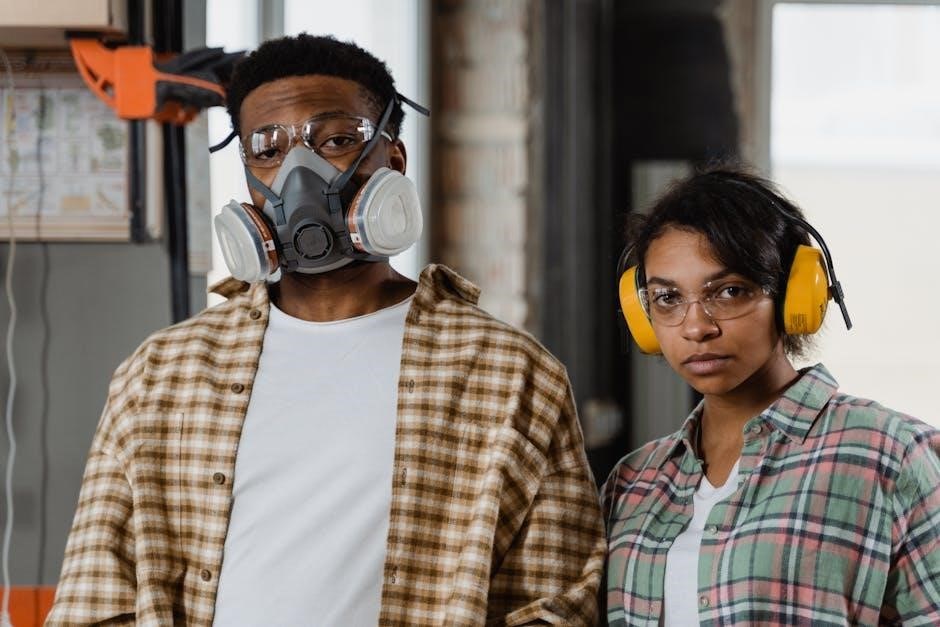

Protective Gear and Workshop Safety

Protective gear is essential for ensuring safety while working on your miter saw table project. Always wear safety glasses to shield your eyes from debris and dust. Gloves provide grip and protect your hands from cuts and splinters. A dust mask is crucial for preventing inhalation of sawdust and particles. Hearing protection, such as earplugs, is recommended due to the loud noise of power tools. Steel-toe shoes or sturdy footwear can prevent foot injuries in case of accidents. Keep your workshop clean and well-lit to avoid tripping hazards. Ensure proper ventilation to reduce dust accumulation. Store tools and materials neatly, and keep children and pets away from the workspace. Always have a fire extinguisher and first aid kit nearby. By prioritizing protective gear and maintaining a safe workshop environment, you can minimize risks and ensure a successful project.

Understanding Your Miter Saw’s Specifications

Understanding your miter saw’s specifications is crucial for building a compatible table. A miter saw is a crosscut tool that cuts wood across the grain, with an adjustable head for precise angles. Common blade sizes range from 8 to 12 inches, affecting the table’s design. Motor power, typically between 10-15 amps, determines cutting capacity. Look for features like laser guides, adjustable fences, and dust collection ports. The saw’s weight and dimensions dictate the table’s stability and size. Ensure the table accommodates the saw’s maximum cutting capacity and includes space for attachments. Matching the table design to your saw’s specs ensures optimal performance and safety, making your project more efficient and accurate.

Materials and Tools Required

Gather essential materials like 2×4 lumber, screws, bolts, and wood glue. Tools needed include drills, saws, wrenches, and measuring tapes for precise assembly and adjustments.

List of Lumber and Hardware Needed

Start by gathering 2×4 lumber for the frame and legs, ensuring stability and durability. You’ll also need 3/4-inch plywood or MDF for the table top and shelves. Additional materials include 2×6 boards for supports, wood screws, bolts, and wood glue. For the folding wings, 2×2 lumber and hinges are necessary. Fasteners like lag screws and washers will secure the miter saw firmly. Hardware such as drawer slides or handles can be added for storage compartments. Sandpaper and paint or stain are optional for finishing. Always double-check the cut list provided in your PDF plans and adjust quantities based on your specific design or saw model requirements.

Tools You’ll Need for Assembly

Gather essential tools to ensure a smooth assembly process. Start with a miter saw or circular saw for precise cuts, and use a drill press or handheld drill for screw holes. An impact driver or screwdriver is necessary for securing bolts and screws. Sandpaper and a sander will help smooth out rough edges. A tape measure, square, and clamps are vital for accurate alignment and stability. A level ensures the table is properly aligned. Pencils and markers are needed for marking cut lines. Safety glasses and a dust mask are crucial for protecting yourself while sawing and sanding. Having all these tools ready will streamline your project and ensure professional-grade results.

Optional Features for Customization

Elevate your miter saw table with optional features to enhance functionality. Add storage compartments or bins to keep tools and accessories organized. Incorporate folding wings for extra support when cutting long materials, and consider mobile casters for easy workshop repositioning. A built-in vice can improve material clamping, while cable management systems keep cords tidy. Customizing your table with these features allows you to tailor it to your specific needs, ensuring efficiency and comfort during projects. These additions can transform your miter saw table into a versatile workstation,perfect for both small and large-scale woodworking tasks.

Step-by-Step Assembly Instructions

Assemble the saw base, attach side tables, and adjust the height for a level surface. Add folding wings for extra support. Follow the steps to create a functional workstation.

Preparing the Saw Base and Table Top

Start by cutting the plywood or MDF to the desired size for the table top. Sand the surface to ensure it’s smooth and even. Assemble the saw base using 2×4 lumber, ensuring it is sturdy and can support the weight of the miter saw. Attach the saw base to the table top, aligning it precisely. Use clamps to hold it in place while drilling pilot holes and securing it with screws. Ensure the table top is level by adjusting the saw base as needed. This step is crucial for accuracy in your cuts. Allow the assembly to dry before moving on to the next steps.

Assembling the Side Tables and Supports

Cut the 2×4 lumber to the required lengths for the side tables and supports. Assemble the side tables by attaching the legs and frames using screws. Ensure the tables are level and securely fasten them to the main table top. Add supports between the side tables and the main frame for additional stability. Use brackets or clamps to reinforce the joints. Sand all surfaces to ensure smooth edges. Attach the side tables to the main table top, ensuring proper alignment. This step provides extra workspace and support for longer materials. Double-check all connections for tightness before proceeding. Proper assembly ensures stability and prevents wobbling during use.

Attaching the Miter Saw to the Table

Position the miter saw on the table top, ensuring it is centered and aligned with the pre-drilled holes. Use the manufacturer’s bolts to secure the saw to the table. Tighten evenly to prevent wobbling. Double-check that the saw’s base is flush with the table surface for accurate cuts. Use a carpenter’s square to verify alignment. Once secured, test the saw’s movement to ensure it operates smoothly. Finally, adjust the saw’s height if necessary to match the table’s surface level. Proper attachment ensures precision, safety, and optimal performance during cutting tasks.

Adding Folding Wings for Extra Support

Enhance your miter saw table’s functionality by adding folding wings, ideal for supporting long or wide workpieces. Attach the wings to the table using hinges, allowing them to fold up when not in use. Install support brackets to ensure stability and prevent sagging. Use 2×4 lumber for the wings and metal brackets for durability. Align the wings with the table surface and secure them tightly. This addition provides extra workspace, making it easier to handle large materials. Folding wings are a practical customization, maximizing convenience while saving space in your workshop. They are especially useful for projects requiring consistent support across extended lengths.

Design Variations and Customization

Explore versatile designs, from mobile stands to space-saving folding tables with storage solutions. Customize your miter saw table to fit your workshop needs and project requirements.

Mobile Miter Saw Stand Designs

Mobile miter saw stands offer flexibility and space-saving convenience. Plans often include collapsible wings for extra support and wheels for easy transport. These designs are ideal for workshops with limited space or for professionals who need to move their tools frequently. Many free PDF plans provide step-by-step instructions for building a sturdy, portable stand using materials like plywood or 2×4 lumber. Optional features such as foldable sides and adjustable legs ensure versatility. With a mobile miter saw stand, you can improve workflow and reduce clutter in your workspace. These designs are perfect for DIY enthusiasts and woodworkers seeking a practical, customizable solution for their projects.

Space-Saving Folding Miter Saw Tables

Folding miter saw tables are perfect for small workshops or tight spaces. These designs feature collapsible wings and foldable frames, allowing easy storage when not in use. Many free PDF plans include step-by-step instructions for building a table with adjustable legs and a compact footprint. Some designs incorporate hinges for quick assembly and disassembly, making them ideal for DIY enthusiasts with limited space. By combining portability and functionality, these tables provide a practical solution for woodworkers who need a sturdy workspace without sacrificing valuable storage space. They are a great option for optimizing your workshop layout while maintaining precision and versatility in your projects.

Incorporating Storage Solutions

Add functionality to your miter saw table by incorporating storage solutions. Free PDF plans often include designs for built-in shelves, drawers, or compartments to organize tools and accessories. These features help keep your workspace clutter-free and ensure essential items are within easy reach. Some designs integrate cabinets or bins for storing saw blades, clamps, and other small parts. By combining a sturdy work surface with practical storage, you create a more efficient and organized workshop. These additions maximize space and enhance productivity, making your miter saw table a versatile hub for your woodworking projects. Customizable storage options ensure your workspace meets your specific needs.

Troubleshooting Common Issues

Address uneven surfaces, wobbly tables, and alignment problems. Check the frame for stability, use shims for leveling, and ensure the saw is securely attached for accurate cuts.

Ensuring the Table Surface is Level

A level table surface is crucial for accurate cuts. Start by placing the miter saw table on a flat, stable floor. Use a carpenter’s level to check the table’s surface. If uneven, adjust the legs or use shims to stabilize the base. Ensure the table top aligns perfectly with the miter saw’s cutting surface. Tighten all bolts securely to prevent any movement. For added precision, use a spirit level to verify the surface in multiple directions. If building from plans, double-check the frame assembly for squareness to avoid unevenness. A level table guarantees consistent results and prevents unsafe cutting conditions. Regular checks maintain accuracy over time.

Adjusting the Saw Height for Accuracy

Proper saw height adjustment ensures precise cuts and prevents errors. Loosen the mounting bolts and raise or lower the miter saw to align the blade with the table surface. Use a combination square or ruler to measure the blade’s exposure—1/8 inch above the table is ideal. Tighten the bolts securely after adjustment. Check the cut quality on scrap wood to verify accuracy. For optimal performance, ensure the saw’s fence is parallel to the table edge. Adjustments may vary depending on the project requirements. Refer to your free PDF plans for specific measurements and diagrams to achieve the perfect setup. Accurate alignment enhances both safety and cutting precision.

Fixing Wobbly or Unstable Tables

A wobbly table compromises accuracy and safety. Inspect the table legs for unevenness or loose joints. Tighten all bolts and screws, ensuring the frame is rigid. If instability persists, add stability brackets or corner supports. Sand any uneven legs to level the table. For added rigidity, attach the table to a sturdy base or use locking casters. Check the miter saw’s mounting hardware and ensure it’s securely fastened. A stable workspace is crucial for precise cuts and safe operation. Refer to your free PDF plans for reinforcement techniques and ensure your table is rock-solid before resuming work. Stability is key to achieving professional-quality results.

Complete your miter saw table project with confidence. Test all features thoroughly and maintain the table regularly. Share your success and enjoy your new workstation!

Final Assembly and Testing

Once all components are assembled, ensure the miter saw is securely attached and the table surface is perfectly level. Test the setup by making sample cuts to verify accuracy and stability. Check that the folding wings, if installed, function smoothly and provide adequate support. Use clamps or stops to ensure consistent results. Sand any rough edges for a professional finish. Finally, apply a protective coating to the table surface to prevent damage. Plug in your miter saw and run a few trial cuts to ensure everything operates seamlessly. If satisfied, your custom miter saw table is ready for your next woodworking project!

Maintenance and Upkeep of Your Miter Saw Table

Regularly clean the table surface to prevent dust and debris buildup, ensuring smooth operation. Inspect bolts and screws for tightness and retighten as needed. Lubricate moving parts, such as folding wings, to maintain smooth functionality. Store the table in a dry, protected area when not in use to avoid damage from moisture. Periodically check for wear on the table top and apply a protective finish if necessary. Sharpen or replace the miter saw blade as needed to maintain cutting accuracy. Always unplug the saw when performing maintenance. By following these steps, you’ll extend the life of your miter saw table and ensure optimal performance for years to come.

Sharing Your Project and Getting Feedback

Sharing your miter saw table project is a great way to connect with other DIY enthusiasts and gain valuable insights. Post photos and descriptions of your build on social media, forums, or woodworking communities. Include details about the materials, tools, and challenges you faced. Request feedback to identify areas for improvement and learn new techniques. Many creators find that sharing their work helps them refine their skills and inspires others. Consider sharing your project on platforms like Pinterest, Instagram, or YouTube, where woodworking projects often gain traction. By engaging with the DIY community, you can gain recognition, support, and ideas for future projects.