Understanding the ZF 6HP21 EDS3 Solenoid Diagram

The ZF 6HP21 EDS3 solenoid diagram is a crucial component in the maintenance and repair of this transmission system. It provides a visual representation of the solenoids location, connections, and interaction with other transmission components. Understanding this diagram is essential for anyone working on or interested in the ZF 6HP21 transmission.

Introduction to the ZF 6HP21 Transmission

The ZF 6HP21 transmission is a six-speed automatic transmission renowned for its smooth shifting, durability, and efficiency. Developed by ZF Friedrichshafen AG, a leading automotive supplier, the 6HP21 has gained widespread popularity across various vehicle manufacturers. It’s found in a wide range of vehicles, including BMW, Audi, and Land Rover, and is known for its robust construction and advanced electronic control system.

The 6HP21 transmission incorporates a sophisticated hydraulic system that utilizes a series of solenoids to manage fluid pressure, enabling smooth gear changes. These solenoids are electronically controlled by the transmission control unit (TCU), which receives signals from various sensors throughout the vehicle. This intricate interplay between hydraulics and electronics ensures precise and responsive gear selection.

The 6HP21 transmission’s design features include a torque converter, planetary gear sets, and a valve body that houses the solenoids. The torque converter allows for smooth acceleration, while the planetary gear sets provide the necessary gear ratios for efficient power delivery. The valve body is a critical component, as it controls the flow of hydraulic fluid to the clutches and brakes, ultimately determining gear engagement.

The ZF 6HP21 transmission is a complex yet ingenious piece of engineering that has revolutionized the automotive landscape. Its reliable performance, coupled with its advanced design features, has earned it a place as a benchmark in the industry. Understanding the intricacies of this transmission, including its hydraulic system and electronic controls, is crucial for ensuring its optimal performance and longevity.

Understanding the EDS3 Solenoid

The EDS3 solenoid, also known as the “Electronic Direct Shift 3” solenoid, is a crucial component within the ZF 6HP21 transmission’s hydraulic system. This solenoid plays a vital role in controlling the engagement and disengagement of the transmission’s clutches, directly influencing the gear selection process. Specifically, the EDS3 solenoid governs the application of the “E” clutch, which is responsible for engaging the third and fourth gears.

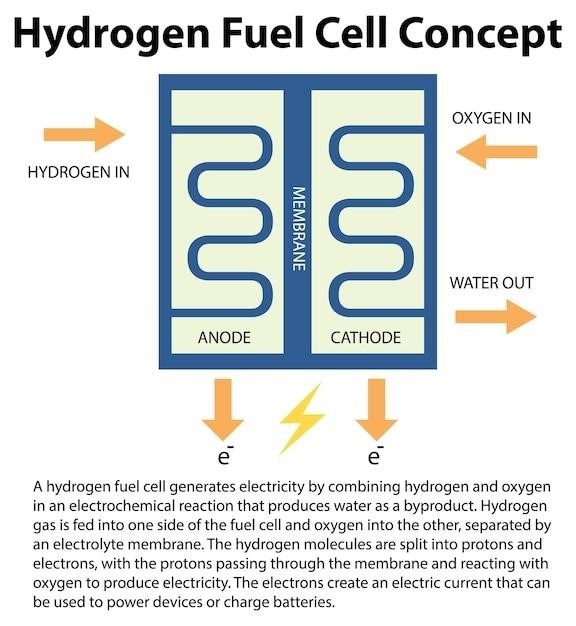

The EDS3 solenoid operates through an electromagnetic principle. When the transmission control unit (TCU) sends an electrical signal to the solenoid, it activates a magnetic field. This field, in turn, pushes a piston within the solenoid, altering the flow of hydraulic fluid. By controlling the pressure and direction of hydraulic fluid, the solenoid engages or disengages the E clutch, facilitating smooth gear transitions.

The EDS3 solenoid’s function is intricately linked to the operation of other solenoids within the 6HP21 transmission. It interacts with the EDS2, EDS4, and EDS5 solenoids, which control the other clutches within the transmission. The precise coordination of these solenoids ensures seamless gear changes and optimal performance. Understanding the EDS3 solenoid’s role and its interaction with other solenoids is crucial for diagnosing transmission problems, especially those related to gear slippage or erratic shifting behavior.

In the context of the ZF 6HP21 EDS3 solenoid diagram, this solenoid is often depicted as a yellow-capped component, visually highlighting its importance within the transmission’s hydraulic system. This visual representation serves as a valuable tool for mechanics and technicians seeking to understand the function and interconnection of the transmission’s various components.

Importance of the ZF 6HP21 EDS3 Solenoid Diagram

The ZF 6HP21 EDS3 solenoid diagram is not merely a collection of lines and symbols; it serves as a vital tool for understanding the complex hydraulic system of the ZF 6HP21 transmission. This diagram provides a visual roadmap of the solenoid’s function, its connections to other components, and its role in the overall transmission operation. It is an indispensable resource for mechanics, technicians, and even enthusiasts who seek to delve into the intricacies of this sophisticated transmission.

For mechanics, the EDS3 solenoid diagram acts as a guide for diagnosing and troubleshooting transmission problems. By tracing the flow of hydraulic fluid through the diagram, they can pinpoint potential points of failure, such as a malfunctioning solenoid, a blocked valve, or a leak in the hydraulic system. This visual aid allows them to quickly identify the root cause of transmission issues, leading to efficient repairs and reduced downtime.

The diagram also assists in understanding the interactions between different solenoids and the transmission’s control unit (TCU). It helps mechanics comprehend how electrical signals from the TCU activate the solenoids, controlling clutch engagement and disengagement for seamless gear shifts. This deeper understanding allows for more effective troubleshooting of transmission problems, especially those related to electronic control issues.

For enthusiasts and hobbyists, the EDS3 solenoid diagram provides a clear and concise representation of the transmission’s inner workings. It allows them to appreciate the engineering complexity of the ZF 6HP21 transmission and understand how the various components work together to deliver smooth and efficient power transfer. This visual aid can be particularly helpful when performing routine maintenance or upgrading components, ensuring a deeper understanding of the transmission’s operation.

Components of the ZF 6HP21 EDS3 Solenoid Diagram

The ZF 6HP21 EDS3 solenoid diagram is a detailed visual representation of the transmission’s hydraulic system, specifically focusing on the solenoids that control fluid flow and clutch engagement. The diagram typically consists of several key components, each playing a critical role in the transmission’s operation⁚

Solenoids⁚ These are the core components of the diagram, represented by distinct symbols. Each solenoid is labeled with its designation (e.g., EDS3, EDS5) and its function. The diagram highlights the position of each solenoid within the valve body and its connection to the hydraulic circuit. The colors used for the solenoids often correspond to their function, such as yellow for pressure control solenoids and blue for shift solenoids.

Hydraulic Lines⁚ These are represented by lines connecting the solenoids and other components. They depict the flow of hydraulic fluid throughout the transmission, indicating the path taken by the fluid to activate clutches, apply pressure, and engage different gears. The diagram might also include arrows to show the direction of fluid flow.

Valve Body⁚ The valve body is the heart of the hydraulic system, housing the solenoids and valves that control fluid flow. The diagram often includes a simplified representation of the valve body, showing the location of the solenoids and their relative positions within the unit. This visual aid helps understand the physical layout of the system.

Clutch Packs⁚ These are the components responsible for engaging and disengaging gears. The diagram might not show the exact position of clutch packs, but it indicates the hydraulic lines connected to each clutch pack, highlighting how solenoids control their engagement and disengagement.

Other Components⁚ Depending on the complexity of the diagram, it might also include additional components like pressure regulators, filters, and sensors, providing a more comprehensive overview of the transmission’s hydraulic system.

Benefits of the EDS3 Solenoid Diagram

The ZF 6HP21 EDS3 solenoid diagram offers numerous benefits for mechanics, technicians, and anyone involved in the maintenance and repair of this transmission system. It provides a comprehensive visual representation of the hydraulic system, enabling a deeper understanding of its operation and troubleshooting potential issues. The benefits include⁚

Simplified Troubleshooting⁚ The diagram acts as a visual guide, allowing technicians to identify the specific solenoid responsible for a particular issue. By tracing the hydraulic lines and identifying the connected solenoid, they can pinpoint the root cause of a transmission problem, such as a faulty solenoid, a blocked hydraulic line, or a malfunctioning valve body. This visual representation makes troubleshooting more efficient and accurate.

Enhanced Understanding⁚ The diagram provides a clear picture of the hydraulic system’s layout and function. It clarifies the connection between the solenoids, valves, clutch packs, and other components, allowing for a more comprehensive understanding of how the transmission works. This knowledge is essential for diagnosing complex issues and implementing effective repair strategies.

Improved Communication⁚ The diagram serves as a common language for technicians and mechanics, ensuring clear communication about specific components, their location, and their function within the transmission system. This shared understanding facilitates more effective collaboration and problem-solving during repair procedures.

Reduced Repair Time⁚ By quickly identifying the source of a problem, the diagram helps streamline the repair process. Technicians can directly target the faulty component, saving valuable time and minimizing downtime for the vehicle. This efficiency translates into lower repair costs and quicker turnaround times.

Preventative Maintenance⁚ Understanding the diagram allows for better preventative maintenance. By regularly inspecting the solenoids and hydraulic lines, technicians can identify potential issues before they escalate into major problems. This proactive approach helps maintain the transmission’s performance and prolong its lifespan.

Overall, the ZF 6HP21 EDS3 solenoid diagram is an invaluable tool for anyone working with this transmission. It fosters a deeper understanding of the system, enables efficient troubleshooting, and promotes effective communication, ultimately leading to faster and more reliable repairs.

Symptoms of a Failing EDS3 Solenoid

A failing EDS3 solenoid in the ZF 6HP21 transmission can manifest in a variety of symptoms that indicate a potential issue requiring attention. These symptoms can range from subtle to severe, and their appearance can vary depending on the severity of the solenoid malfunction. It is crucial to be aware of these signs to address the problem promptly and prevent further damage to the transmission;

Rough Shifting⁚ One of the most common symptoms of a failing EDS3 solenoid is rough shifting. The transmission may struggle to engage gears smoothly, resulting in jerky or hesitant shifts. This can be particularly noticeable when accelerating or decelerating, especially during low-speed maneuvers. The transmission may also feel sluggish, resulting in delayed acceleration or a lack of responsiveness.

Slippage⁚ A failing EDS3 solenoid can lead to transmission slippage. This occurs when the transmission loses its ability to hold gears properly, resulting in a slipping sensation or a feeling of the engine revving up without corresponding acceleration. Slippage can also manifest as a “hunting” behavior, where the transmission repeatedly shifts between gears in an attempt to find the correct gear ratio.

Overheating⁚ A malfunctioning EDS3 solenoid can cause the transmission to overheat. This is because the solenoid’s failure can disrupt the hydraulic system, leading to increased pressure and reduced efficiency. Overheating can cause damage to the transmission fluid and other components, potentially leading to further problems.

Transmission Failure⁚ In severe cases, a failing EDS3 solenoid can lead to complete transmission failure. This can occur when the solenoid’s malfunction causes a breakdown in the hydraulic system, rendering the transmission unable to operate properly. In such cases, the vehicle may become undrivable, requiring immediate repair.

If you experience any of these symptoms, it is recommended to consult a qualified mechanic to diagnose the problem and determine whether the EDS3 solenoid requires replacement. Early detection and intervention can prevent further damage and ensure the longevity of your transmission.

Diagnosing and Troubleshooting EDS3 Solenoid Issues

Diagnosing and troubleshooting issues with the EDS3 solenoid in a ZF 6HP21 transmission requires a systematic approach involving specialized tools and knowledge. Identifying the root cause of the problem is crucial for ensuring effective repairs and preventing future issues.

Diagnostic Tools⁚ A scan tool capable of reading transmission codes is essential. This tool will provide valuable information about the transmission’s electronic control unit (ECU) and identify any fault codes related to the EDS3 solenoid. A digital multimeter is also necessary for testing the solenoid’s electrical circuits and verifying proper voltage and resistance readings.

Visual Inspection⁚ Inspect the solenoid for signs of physical damage, such as corrosion, cracks, or debris. Also, check for any loose or damaged wiring connections. A thorough visual inspection can often provide clues to the cause of the problem.

Resistance Testing⁚ Use the multimeter to test the solenoid’s resistance. Compare the measured resistance values with the specifications provided in the ZF 6HP21 EDS3 solenoid diagram or repair manual. Deviations from the expected resistance range indicate a potential issue with the solenoid itself.

Voltage Testing⁚ Measure the voltage at the solenoid’s terminals while the engine is running. Ensure that the voltage is within the specified range for the solenoid. If the voltage is low or absent, there may be a problem with the wiring or the ECU.

Fluid Analysis⁚ Check the transmission fluid level and condition. Contaminated or low fluid levels can contribute to solenoid problems. If the fluid appears dark, burnt, or has a strong odor, it may indicate internal transmission wear, which could also affect the solenoid.

Pressure Testing⁚ For more advanced diagnostics, a pressure test can be performed on the transmission’s hydraulic system. This test can identify problems with hydraulic pressure, which can be caused by solenoid issues or other transmission components.

By following these steps, you can systematically diagnose and troubleshoot issues with the EDS3 solenoid, ensuring accurate identification of the problem and effective repair.

Replacing the ZF 6HP21 EDS3 Solenoid

Replacing the EDS3 solenoid in a ZF 6HP21 transmission is a relatively straightforward procedure, but it requires careful attention to detail and proper tools. It is recommended to have access to a repair manual or a comprehensive guide that provides detailed instructions and diagrams for the specific transmission model.

Preparation⁚ Before starting the replacement, it is essential to ensure that the vehicle is safely parked on a level surface, the engine is cool, and the battery is disconnected. Gather the necessary tools, including a socket wrench set, a torque wrench, a flat-blade screwdriver, and a new EDS3 solenoid that is compatible with your transmission.

Access the Solenoid⁚ Locate the EDS3 solenoid on the transmission valve body. It is typically identified by a yellow cap and may be labeled with the part number 702J. Remove any surrounding components, such as the air intake or the exhaust system, that may obstruct access to the solenoid.

Disconnect the Solenoid⁚ Disconnect the electrical connectors and the hydraulic lines attached to the solenoid. Be careful not to damage the connectors or the lines during this process. Label the connectors and lines if necessary to ensure proper re-installation.

Remove the Solenoid⁚ Remove the solenoid from the valve body using the appropriate tools. Carefully note the position and orientation of the solenoid for proper re-installation;

Install the New Solenoid⁚ Install the new solenoid in the same position and orientation as the old one. Ensure that the solenoid is properly seated and tightened to the specified torque. Reconnect the hydraulic lines and electrical connectors, making sure they are securely fastened.

Test and Reassemble⁚ After installing the new solenoid, reconnect the battery, start the engine, and test the transmission for proper operation. If any issues arise, double-check the connections and consult the repair manual or a professional mechanic.

Replacing the EDS3 solenoid can resolve shifting problems, improve transmission performance, and enhance overall vehicle reliability. Remember to follow the proper procedures and use the correct tools to ensure a successful replacement.